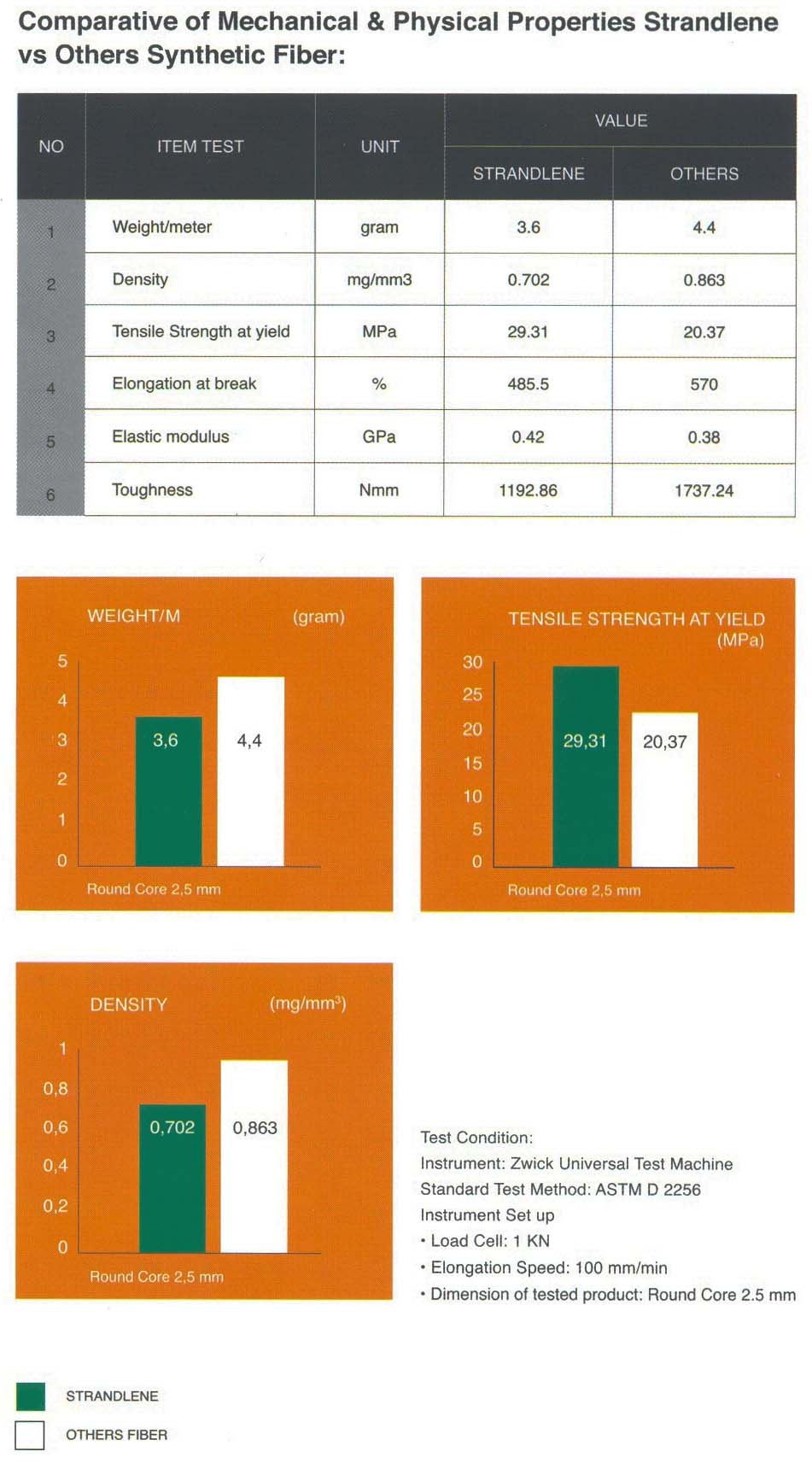

Strandlene is produced by integrating a ground-breaking formulation with a matchless molding and tooling method, specifically designed by PT. Ecoplast Asia’s Research and Development (R&D) Division. Aside from that, Strandlene becomes the first synthetic fiber in Indonesia that has succeeded in effectively integrating two different materials into the synthetic fiber: High Density Polyethylene (HDPE) and Polyamide (PA) fiber. The perfecr synergy between these two top quality materials makes Strandlene the best synthetic fiber with greatly improved performance in all aspects, which include improvements in tensile strength, performance, weight, elasticity and flexibility compared to other existing synthetic fibers in the market.

Strandlene is produced by integrating a ground-breaking formulation with a matchless molding and tooling method, specifically designed by PT. Ecoplast Asia’s Research and Development (R&D) Division. Aside from that, Strandlene becomes the first synthetic fiber in Indonesia that has succeeded in effectively integrating two different materials into the synthetic fiber: High Density Polyethylene (HDPE) and Polyamide (PA) fiber. The perfecr synergy between these two top quality materials makes Strandlene the best synthetic fiber with greatly improved performance in all aspects, which include improvements in tensile strength, performance, weight, elasticity and flexibility compared to other existing synthetic fibers in the market.

By using strandlene istead of using other brand of synthetic fibers, furniture manufacturers can gain more advantages. With the physically lightweight and high strength material, but still very flexibel, furniture manufacturers will then need fewer synthetic fibers to create stylish outdoor and indoor wicker furniture.

Strandlene is available in round core design or pattern, and comes in a variety of sizes, ranging from diameter 2.0mm, 2.2mm, 2.5mm, 3.0mm, and 4.0mm.